INSTALLING RAIL PANELS IS EASY!

Installation of Lines panels by ScandiWall is a simple task even with minimal construction skills.

Our slatted panels can be fixed with both liquid nails and self-tapping screws.

The LINES panel is completely ready for installation: the slats are assembled on an acoustic felt base, which reduces installation time several times compared to individual slats.

Slatted panels are easy to install not only at the stage of major repairs, but also to decorate an existing interior.

DO I NEED TO PREPARE THE WALL?

Usually, no. Since the panels have a base, there is no need to prepare and paint the walls. The only thing is that the wall should be flat and strong. The weight of the panels is minimal, so they can be mounted on absolutely any surface. Including the ceiling.

WHAT TOOLS YOU WILL NEED

- Level

- Pencil

- Liquid nail glue (with the gluing method)

- Drill, screwdriver

- Self-tapping screws (we recommend black ones with a cap).

- Stationery knife

- Circular saw or hacksaw.

PREPARATION AND STAGES OF WORK

1. Measure the width and height of the area to be installed and check the levels. Remove the skirting board if necessary.

2. Trim the panels based on the measurements. For more information on trimming, see below.

3. Mount the panels using one of the methods described below.

METHOD 1. GLUING THE PANEL TO THE WALL.

We recommend using high-quality liquid nail adhesives, which are available with a quick fixation, to simplify installation. Approximate consumption: 1 tube of adhesive (300-400 g) is enough for about 3 m2 of panel. Thus, for one 600*2700 panel, about 1/2 tube of glue is used.

Tip: After trimming, place the panel in the desired location before applying the adhesive to make sure you cut correctly.

Apply the adhesive in lines (or dashes), evenly on the felt (on the back side) or directly on the wall. Press the panel gently against the wall. If necessary, hold it for a while. Follow the instructions for the mounting adhesive you are using.

For greater reliability, you can screw the panel with screws after gluing. In this case, 15 screws are enough for the panel (3 pcs in a row in width, 5 such rows in height).

The advantage of this method is its simplicity. Measure and stick the panels on the wall with liquid nails - that's it! Disadvantage: it will be difficult to dismantle the panels from the wall if necessary. Also, the ceiling must be fixed with additional screws (!).

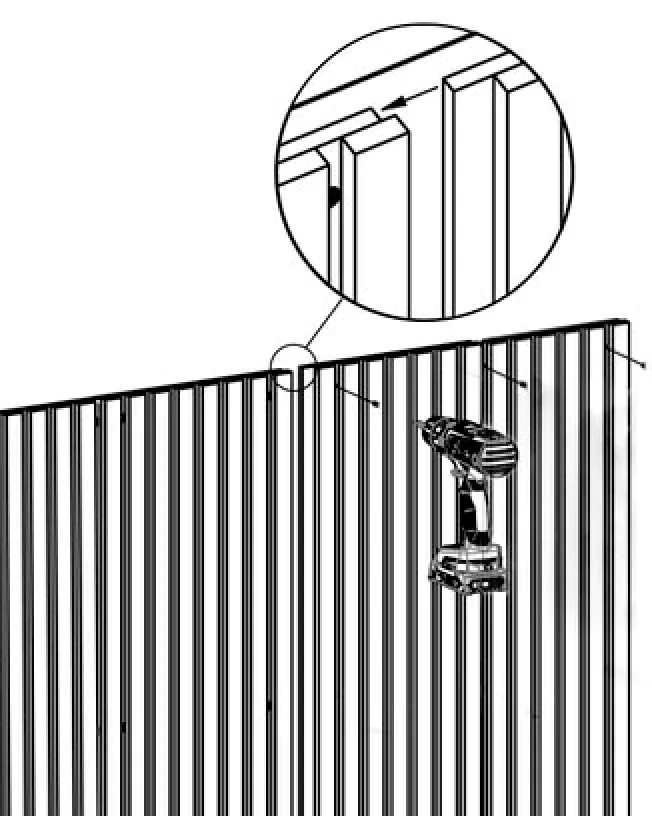

METHOD 2. SCREWING SLATS TO THE WALL OR MOUNTING WITH SCREWS

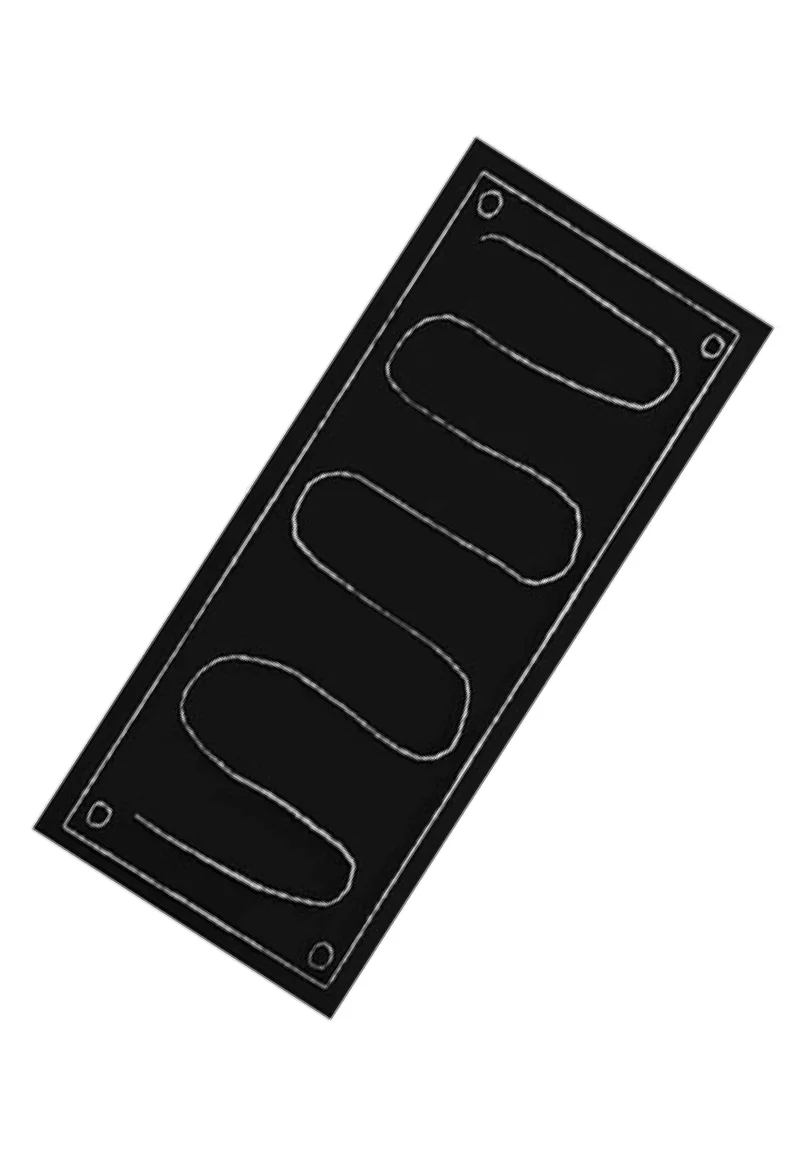

The screws are screwed into the felt between the slats.

Fastening of Lines. It is enough to screw in 3 screws along the width of the panel (this will be a row), with a step of 50-60 cm between the rows vertically. There will be 5 such rows in height. Thus, 15 screws are required for one Lines acoustic panel (for 5 rows).

For mounting the Lines Mini panel 6 screws will be enough.

It can be screwed to mounting slats/bars or directly to the wall. This method of fastening allows the panel to be removed at any time, unlike liquid nails.

Advantages: the panels can be easily dismantled. If you screw them onto a bar or rail, it provides additional sound insulation. Disadvantage: more labor intensity, more space is taken away from the room.

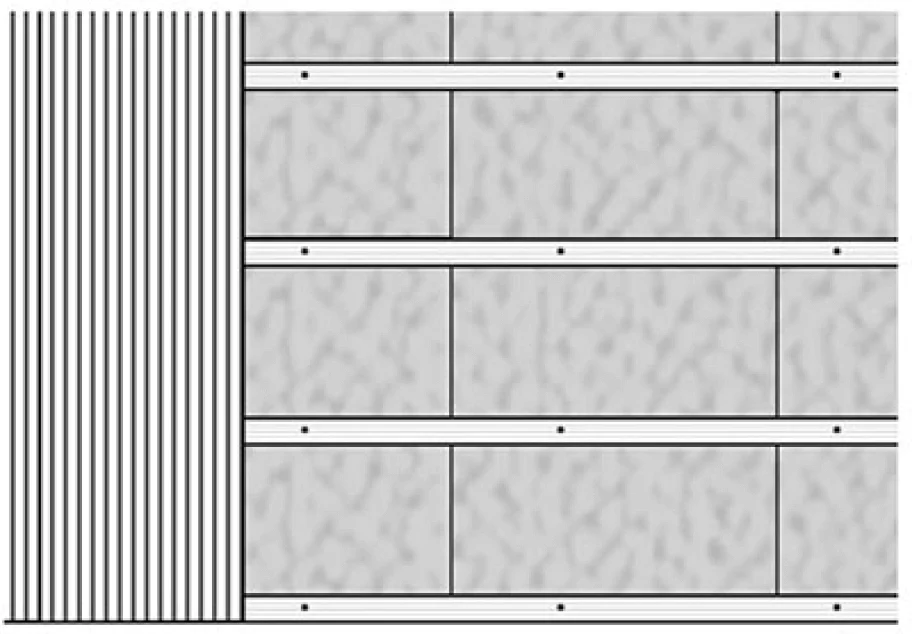

SOUND INSULATION - HOW TO ACHIEVE CLASS "A"?

The slatted panel itself has soundproofing properties, as the slats are mounted on an 8 mm thick acoustic felt backing. When the panels are installed directly on the wall, sound absorption corresponding to approximately Class D is achieved.

To achieve Class A sound insulation (the highest class), you need to mount it on a 45 mm thick beam. Mineral wool or acoustic mats 45 mm thick are placed between the bars. Then screw the panels as in method #2.

This installation method will provide you with a fundamentally better level of acoustic comfort.

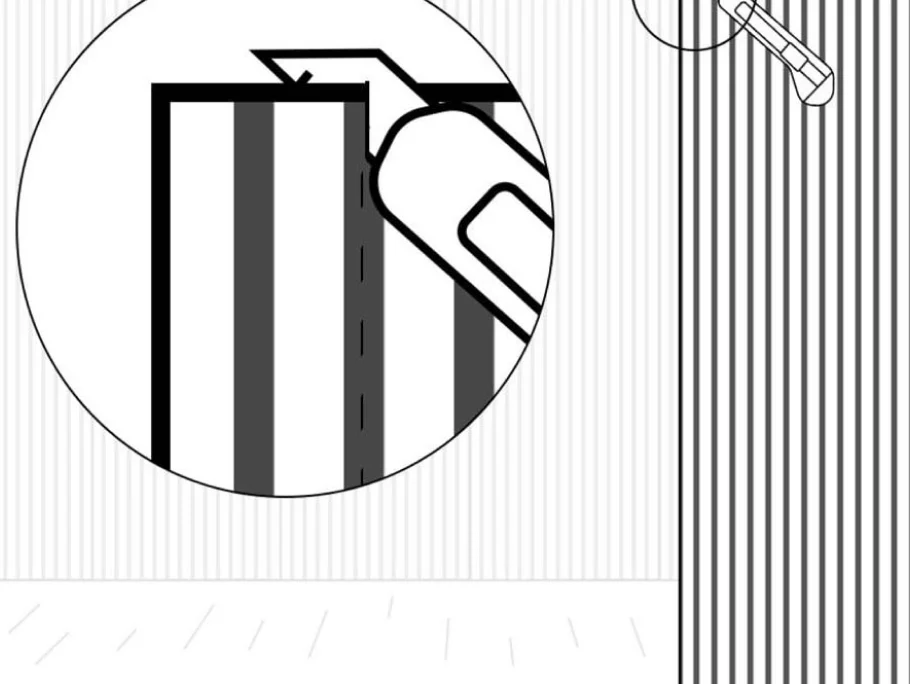

Cutting panels to size

The width of the panel is easy to cut along the seams - since you only need to cut the soft felt backing. A sharp knife, such as a utility knife, is suitable for this purpose.

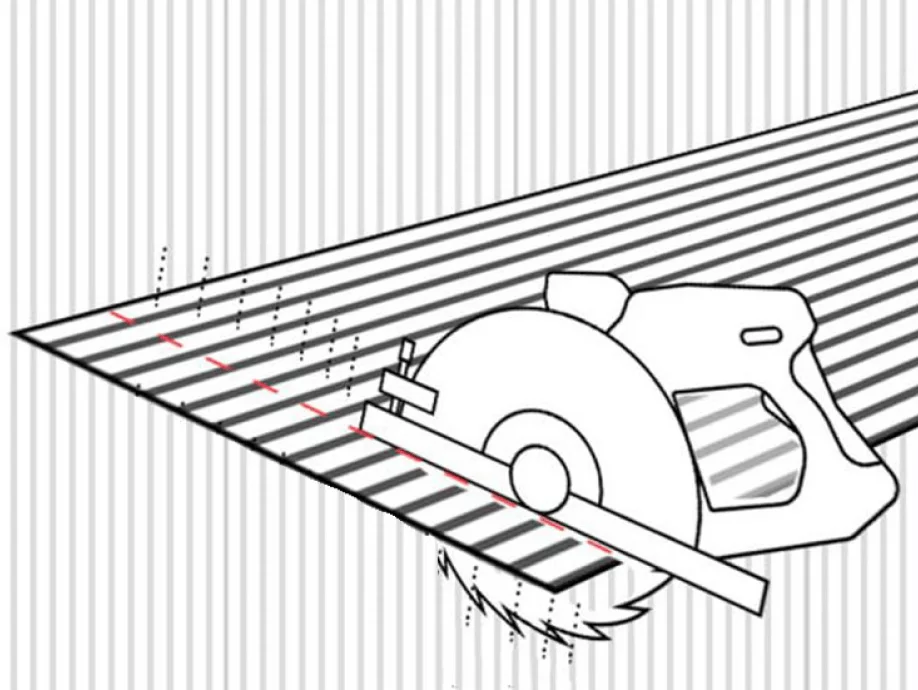

It is best to cut the panel to length with a circular saw. You can also use a hacksaw.

If you have any questions, don't hesitate to call us and we will be happy to advise you.

And share with us photos of your beautiful interiors with slats 🙂.